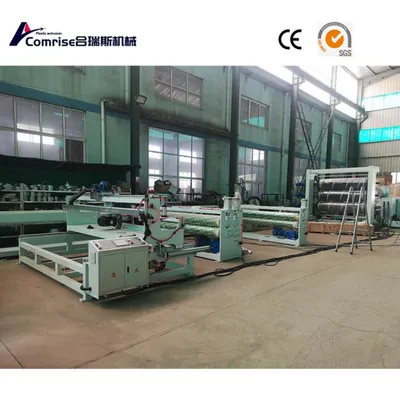

Screw diameter | 120-180mm |

L/D | 33:1 |

Main motor power | 132-280kw |

Sheet thickness | 3-30mm |

Sheet width | 1200-3000mm |

Output | 600-1000kg/h |

Installed power | 200-580kw |